Rust on Brakes: Does It Matter?

Thanks to its toughness, durability, and heat-handling properties, steel has long been the material of choice for building automobile braking system components. In fact, steel is used to create many parts of your car’s braking system—including its brake rotors, brake calipers, and components of the all-important brake pad.

The latter is largely responsible for creating the friction your vehicle uses to stop whenever you press on the brake pedal. And while steel may be tough, it’s not without weaknesses—especially corrosion. Steel rusts when exposed to moisture and if exposed to lots of moisture, combined with road salt, it rusts even faster. In most cases, rust is an eyesore that slowly but surely eats away at the integrity and appearance of your vehicle. Rust in a vehicle braking system, however, can be a far more serious problem for the longevity of braking system parts—and more importantly, for your safety.

The steel parts in your braking system are just as exposed to moisture and corrosion-encouraging road salt as any other part of your vehicle. And, because your brakes are near the road, largely unprotected, and go through numerous heating and cooling cycles on every drive, they’re even more likely to suffer once corrosion sets in.

Some forms of rust in a vehicle braking system are normal, and no cause for alarm.

For instance: brake rotor surfaces may become covered in a thin film of rust if the vehicle is parked outside during a rainstorm or heavy snowfall. Moisture coats the surface of the steel brake rotor, leaving a very thin layer of rust behind. But not to worry—this form of rust is no cause for alarm. Since it’s a thin layer and exists only at the surface of the steel rotor, it will disappear after a few moments of driving as the brake pads rub it off. Every time you press the brakes, the brake pads clean the engaged surface of the brake rotors of contaminants, including light surface rust.

When can rust be a major issue on brake pads?

The foundation of all brake pads is a steel plate – called a ‘backing plate’ – to which the brake pad friction material is attached. And while the brake pad material itself can rust, the rust on the brake pad steel backing plate is the most concerning and dangerous. Over time, this rust can weaken the backing plate considerably, causing brake pad friction material to chip, crack, or even separate entirely, which can result in a drastic loss of stopping power and control.

In many cases, rust can even lead to brake pad seizure.

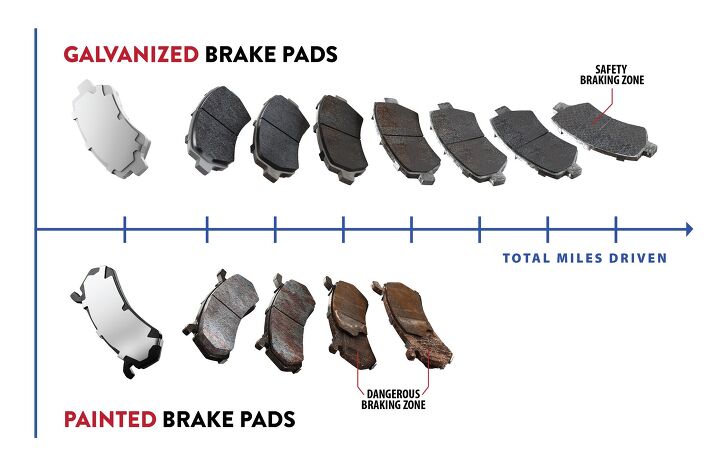

Some manufacturers apply a paint to the steel brake pad backing plate meant to ward off corrosion, but it rarely prevents rust, as paint just chips away or burns off during braking. Once rust finds its way beneath the glue that holds the friction material to the backing plate, a painted brake pad becomes compromised. This can lead to seizing of the brake pad within the caliper, which is a serious safety hazard.

Simply put, once this level of corrosion occurs, you no longer have a complete brake pad—and this is not something that can be “fixed” via sanding or other DIY methods. The only solution is replacement, or again, you run the risk of brake pad seizure.

Related: Brake Replacement: Here’s How To Change Your Brake Pads

Furthermore, rust-related problems with brake pads can even indirectly result in uneven wear, damage and rust to brake rotors as well. To reiterate: once corrosion sets in, brake pads cannot be repaired. They must be replaced.

The nutshell? Brake pad corrosion costs you money, compromises your safety, and may even cause damage to other parts of your braking system—which puts you on a one-way trip to a premature brake-job. So, with brake pad corrosion being a root cause of numerous braking system issues, why don’t manufacturers build brake pads that simply don’t rust?

It’s all a matter of cost.

Many part manufacturers create brake pads and rotors to satisfy a price point, not the desire for long-term durability and maximized life. However, there are several solutions to fend off brake pad rust, along with the many safety and financial issues it may cause. Here, innovative design and materials used in galvanized brake pads are the star of the show, working to eliminate the safety concerns and expense of brake pad corrosion, as well as the dangerous side effect of brake pad material separation and brake pad seizure.

Here’s how NRS brake pads work.

Galvanization makes the backing plates rust-proof to their core—without the use of a painted coating that wears or burns away. Simply put: galvanization protects the brake pad from corrosion, stopping braking system rust problems at their source. Better yet, since galvanized steel is a non-flammable coating, it eliminates the possibility of brake pad ignition and flammability of paint that’s possible in some extreme-use situations.

Related: How to Check Brake Pads

Galvanized brake pads, such as the ones provided by NRS Brakes are specially designed with a Safety Braking Zone, which exists where the brake pad material is mechanically bonded to the corrosion-proof galvanized steel backing plate. Instead of the failure-prone adhesive used in other brake pads, the NRS Safety Braking Zone uses a series of tiny metal hooks, which firmly ‘bite’ into the brake pad friction material, locking it in place.

The result is a corrosion-proof backing plate, with hundreds of corrosion-proof hooks – as opposed to a thin layer of glue – locking in the brake pad material. This makes brake pad material separation impossible, thereby eliminating the two leading causes of premature brake system wear.

Related: How Long Do Brake Pads Last?

As a result, there are a few clear benefits to switching to galvanized brake pads, including: longer brake pad life, reduced waste, longer brake rotor life, and more consistent, predictable stopping power throughout the life of the brake pads. And while there may be less-expensive brake pads out there, ultimately, you’ll be spending more in the long run after corrosion considerably reduces their lifespan. A few extra dollars spent on quality brake pads now could make a massive difference when it comes to both your safety, and your wallet, in the future. Make the switch to galvanized brake pads and you’ll experience superior safety and stopping power, along with measurably longer brake pad life.

Looking for more info? Click here to visit the NRS Brakes site and learn more about the world’s longest lasting brake pads.

More by AutoGuide.com Staff

Comments

Join the conversation